Usually we divide the excavator into two parts: the upper body is mainly responsible for the rotation and operation functions, while the lower body performs the walking function, providing support for the excavator transition and short-distance movement. I am troubled by the common excavator failures such as oil leakage of the rollers, broken supporting sprockets, inability to walk, and inconsistent crawler tightness. This article will explain the functions and related maintenance of "four wheels and one belt". Hope it will be helpful to the majority of owners.

The rollers are used to support the lower frame and disperse the mechanical weight on the track. Due to the uneven installation spacing of the rollers, it is also inconsistent with the track sprocket spacing. The damage of the roller will cause many failures, such as the roller will not rotate, increase the walking resistance and consume the power of the equipment, and the non-rotation of the roller will cause serious wear between the link and the roller.

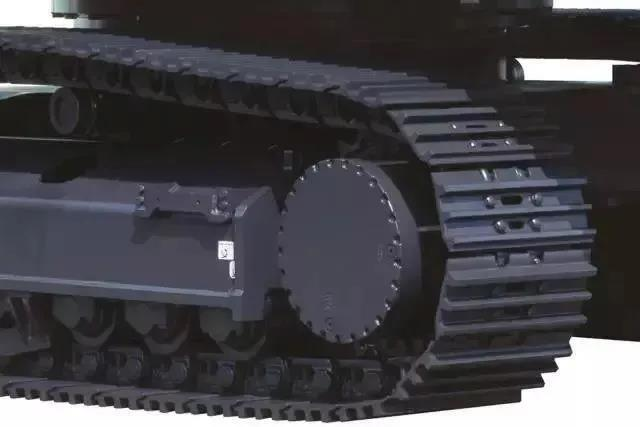

We often say "four-wheeled belt", "four-wheeled" refers to track roller, carrier wheel guide wheel and driving wheel, "one belt" is crawler, they are directly related to the working performance and walking performance of the excavator, so do Good daily maintenance is very important. Usually, it is easy for operators to ignore the cleaning and maintenance of the lower body. The following are the maintenance tips for the "four wheels and one area" of excavators that are necessary for good operators.

During the work, try to avoid the rollers being immersed in the muddy water for a long time. After the work is completed every day, the one-sided crawler should be supported, and the traveling motor should be driven to shake off the soil, gravel and other debris on the crawler;

In winter construction, the roller must be kept dry, because there is a floating seal between the outer wheel and the shaft of the roller;

If there is water, it will freeze at night, and when the excavator is moved the next day, the seal will be scratched in contact with the ice, resulting in oil leakage.

The carrier wheel is located above the X frame, and its function is to maintain the linear motion of the chain rail. If the carrier wheel is damaged, the track chain rail will not be able to maintain a straight line. The carrier wheel is a one-time injection of lubricating oil. If there is oil leakage, it can only be replaced with a new one. During the work, try to avoid the carrier wheel being immersed in muddy water for a long time. Too much dirt and gravel build up hindering the rotation of the idler rollers.

The guide wheel is located in front of the X frame. It consists of the guide wheel and the tensioning spring and oil cylinder installed inside the X frame. It is used to guide the track to rotate correctly, prevent its deviation, track derailment and adjust the tightness of the track. In the process of operation and walking, keep the guide wheel in front, which can avoid abnormal wear of the chain rail, and the tensioning spring can also absorb the impact brought by the road surface during work and reduce wear and tear.

The travel drive device is located at the rear of the X frame, because it is directly fixed on the X frame and has no shock absorption function, and the drive sprocket is fixed on the travel reduction device. Certain impact and abnormal wear will also have adverse effects on the X frame, and the X frame may have problems such as early cracking. The travel motor guard plate can protect the motor, because some dirt and gravel will enter the internal space, which will wear the oil pipe of the travel motor, and the water in the soil will corrode the joints of the oil pipe, so the guard plate should be opened regularly. Clean up the dirt inside.

Post time: Aug-16-2022